Material Saving

High accuracy Less possibility of flash

Offer better protection for molds and platens

Bigger opening stroke

- After sample survey, clamping force efficiency of BOLE central clamping toggle design can reach 100%, Clamping force efficiency of traditional edge clamping force only can reach 80-85%.

- BOLE central clamping toggle design can save 2-5% material for 80% of custome

- Repetitive positioning accuracy of mold opening & closing:± 1mm

- Product weight repetitive accuracy:≤0.5%

- Less possibility of flash, and save flash trim process

- The latest design of clamping structure, averaged force and less distortion for mould platen. Precise low- pressure function for mould closing, proportional pressure control, iso-stress mould platen design, to extend mould life.

- Central clamping structure can provide bigger opening stroke&ejection stroke than other brands' stroke, and can install larger molds easier (Especially for deep cavity working condition.)

Drive System

Fully optimized hydraulic system, improve efficiency. Hydraulic parts from famous international manufactures, ensure machine with reliable performance

- Optimized electrical cabinet design, conform to GB,CE, UL,KCS or other safety standard

- Electrical parts from famous international manufacturer, ensure machine with reliable performance.

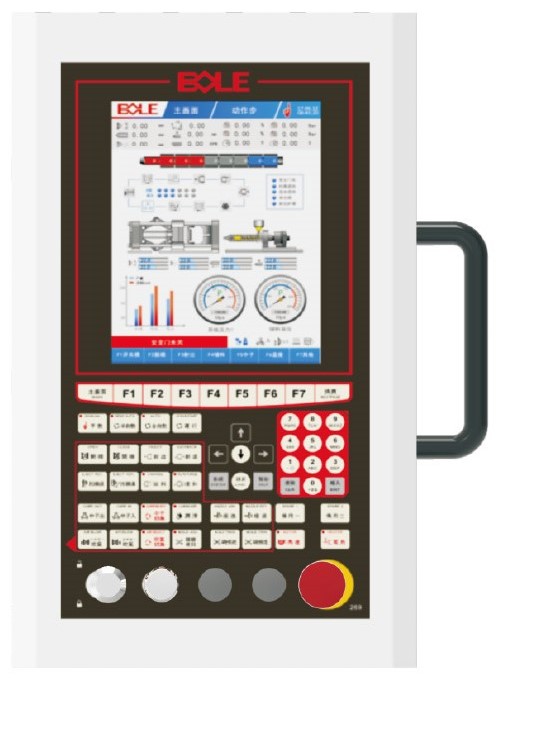

- EST controller is standard.

Inquiry - EKH Hydraulic Servo Energy Saving Injection Moulding Machine